STLBatch - Documentation

Official Online documentation for STLBatch.

Installation :

STLBatch Sorter is a portable application.

Just unzip the zip file into any folder you like.

Only limitation is to have writing privileges at the STLBatch folder.

Usage :

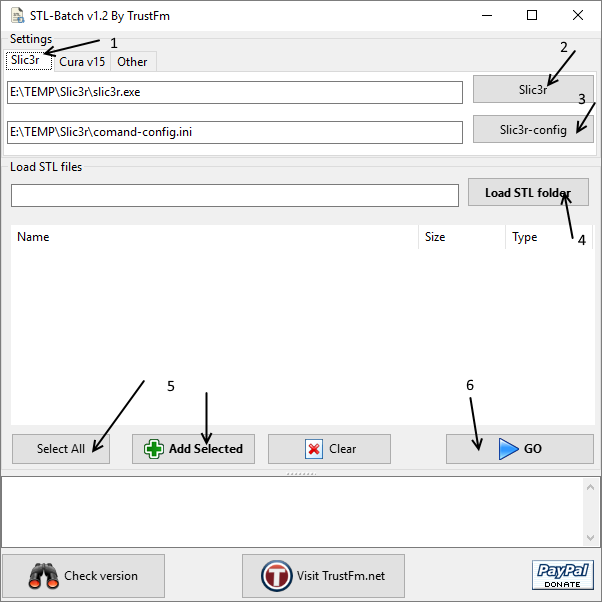

If you want to use Slic3r as slicer for your STL files proceed like this :

1) Hit the Slic3r tab

2) Click the Slic3r and find the slic3r.exe file on your system.

3) Click on the "Slic3r-config" burtton and load the "comand-config.ini".

STLBatch comes with a PLA configuration "comand-config.ini".

If you need other settings use Slic3r in order to generate your custom "comand-config.ini" using "File" > "Export Config" option 4) Put all your STL files into a single folder and click the "Load STL Folder" button.

5) Use "Select All" or "Add Selected" in order to add STL into your process list

6) Click the "Go" button in order to batch convert to gcode al your STL files.

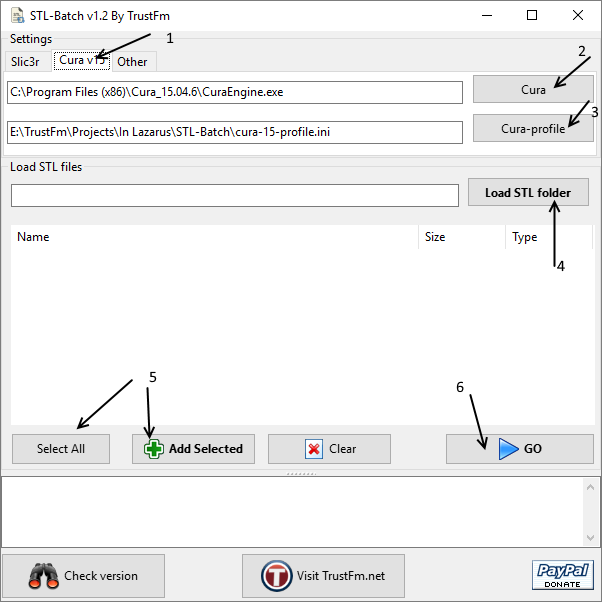

If you want to use Cura 15.X.X as slicer for your STL files proceed like this :

1) Hit the "Cura" tab

2) Click the "Cura" button and find the "CuraEngine.exe" file on your system.

3) Click on the "Cura-profile" burtton and load the "cura-15-profile.ini".

STLBatch comes with a PLA configuration "cura-15-profile.ini".

If you need other settings use atext editor and edit "cura-15-profile.ini"

Unfortunately cura does not export any profiles.

4) Put all your STL files into a single folder and click the "Load STL Folder" button.

5) Use "Select All" or "Add Selected" in order to add STL into your process list

6) Click the "Go" button in order to batch convert to gcode al your STL files.

Below you can see a valid "cura-15-profile.ini" Cura profile

initialSpeedupLayers=4 minimalFeedrate=10 supportXYDistance=700 insetXSpeed=60 retractionZHop=0 extruderOffset[3].X=0 extruderOffset[3].Y=0 retractionSpeed=60 filamentFlow=100 max_acceleration[1]=9000000 infillOverlap=15 skinSpeed=20 inset0Speed=40 coolHeadLift=0 extrusionWidth=399 upSkinCount=4 initialLayerSpeed=20 max_xy_jerk=20000 minimalLayerTime=5 infillSpeed=60 supportExtruder=-1 fanSpeedMax=100 supportType=1 enableCombing=1 fanSpeedMin=100 supportZDistance=150 max_acceleration[3]=10000000 supportEverywhere=0 filamentDiameter=1720 initialLayerThickness=200 supportAngle=60 fanFullOnLayerNr=2 acceleration=3000000 extruderOffset[1].X=0 extruderOffset[1].Y=21600 layerThickness=200 minimalExtrusionBeforeRetraction=20 retractionMinimalDistance=2000 objectSink=0 retractionAmount=800 nozzleSize=400 skirtLineCount=3 max_acceleration[0]=9000000 skirtDistance=0 max_acceleration[2]=100000 extruderOffset[2].Y=0 extruderOffset[2].X=0 perimeterBeforeInfill=0 printSpeed=60 fixHorrible=1 layer0extrusionWidth=400 moveSpeed=150 max_z_jerk=400 supportLineDistance=2666 retractionAmountExtruderSwitch=16500 max_e_jerk=5000 sparseInfillLineDistance=1000 insetCount=3 downSkinCount=4 multiVolumeOverlap=150 -g 49674 posx=100000 posy=100000 startCode=""" M190 S40.000000 M109 S220.000000 ;Sliced at: Fri 29-12-2017 02:16:58 ;Basic settings: Layer height: 0.2 Walls: 1.2 Fill: 40 ;Print time: #P_TIME# ;Filament used: #F_AMNT#m #F_WGHT#g ;Filament cost: #F_COST# ;M190 S40 ;Uncomment to add your own bed temperature line ;M109 S220 ;Uncomment to add your own temperature line G21 ;metric values G90 ;absolute positioning M82 ;set extruder to absolute mode M107 ;start with the fan off G28 X0 Y0 ;move X/Y to min endstops G28 Z0 ;move Z to min endstops G1 Z15.0 F9000 ;move the platform down 15mm G92 E0 ;zero the extruded length G1 F200 E3 ;extrude 3mm of feed stock G92 E0 ;zero the extruded length again G1 F9000 ;Put printing message on LCD screen M117 Printing... """ endCode=""" ;End GCode M104 S0 ; turn off head M140 S0 ; turn off bed G91 ; relative movements G1 Z5 ; Z up 5mm G90 ; back to absolute G28 X0 ; home X axis G28 Y0 ; home Y axis G1 Y200 ; Move Y axis at 200 M84 ; disable motors ;KnightRider M300 S1318 P238 M300 S1396 P119 M300 S1318 P119 M300 S987 P476 M300 S2637 P238 M300 S2793 P119 M300 S2637 P119 M300 S987 P476 M300 S1318 P238 M300 S1396 P119 M300 S1318 P119 M300 S987 P238 M300 S2637 P238 M300 S2349 P952 M300 S0 P476 M300 S0 P952 M300 S1318 P238 M300 S1396 P119 M300 S1318 P119 M300 S987 P476 M300 S2637 P238 M300 S2793 P119 M300 S2637 P119 M300 S987 P476 M300 S1318 P238 M300 S1396 P119 M300 S1318 P119 M300 S987 P238 M300 S2637 P238 M300 S2793 P952 M300 S0 P952 """ preSwitchExtruderCode=""" ;Switch between the current extruder and the next extruder, when printing with multiple extruders. ;This code is added before the T(n) """ postSwitchExtruderCode=""" ;Switch between the current extruder and the next extruder, when printing with multiple extruders. ;This code is added after the T(n) ;Info by TrustFm : ;Generated manually using Cura 15.04.06 by dropping an stl at the plate and then File -> show slice engine log... """Tips :

1) By selecting the "Slic3r" tab you select Slic3r as batch slicer.

If you select the "Cura" tab then your batch slicer will become cura.

2) Other settings :

By checking "Auto-execute" STLBatch will create a bat file and then will execute it immediatelly.

If this setting is not enabled then STLBatch will create the bat file that you should launch it by yourself later.

The bat file is always generated at the same path as the "STLBatch.exe" is located with a formated name like this :

stl-batch-2018-01-07-04-05-11-158

3) Cura 15.04.06 can be found here

4) STLBatch does not work with cura 2.X.X nor 3.X.X