Constructing a TrustFm 3D Printer

SECTION 1 - Aluminum Frame

Section 1 - Aluminum frame : [[ part 1 ]]Last update: 30/12/2023

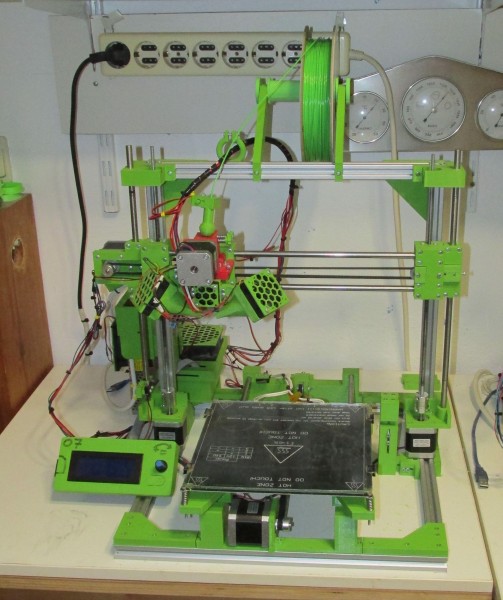

In this website we have seen how to built an i3 Clone 3D printer from scratch.

Now keeping the same spirit we will make a newer version based on aluminum extrusions [V-Slot 2020 1000mm - Natural Anodized].

TrustFm printer will have these extra features that the older project did not covered.

The printer shown here is open source and you can use it comercialy.

The FreeCAD plans will be added in this page soon.

- Sturdy metal frame

- Filament runout sensor

- Power loss sensor

- Full metal direct drive extruder

- Auto Bed Leveling

- Z Fine tuning

- As Z Motion you can use M5 threaded rod or leadscrew type TR8x8(P2) / TR8x2(P2)

- Lower noise and better print quality using TMC2208 stepper drivers intead of the old A4988 ones

- Linear advance enabled using Marlin ver 2.1.2.1

The printer is tested printing PLA, PETG, NinjaFlex and TPU.

Here are some pictures of the finished project

Another take:

More to come soon ...

Section 1 - Aluminum frame : [[ part 1 ]]